Fundamentals on Flexible PCB

PCB is the acronym for Printed Circuit Board. PCB is generally used to support and connect the electrical components with the use of conductive pathways and signal traces. It consists of conductive tracks, pads, and other features which are etched from copper sheets and laminated onto a conductive substrate. It can be single-layered i.e one copper layer or double-layered i.e two copper layers or multi-layered based on the requirement. Based on its specifications it is of various types.

- Single-Sided PCBs.

- Double-Sided PCBs.

- Multilayer PCBs.

- Rigid PCBs.

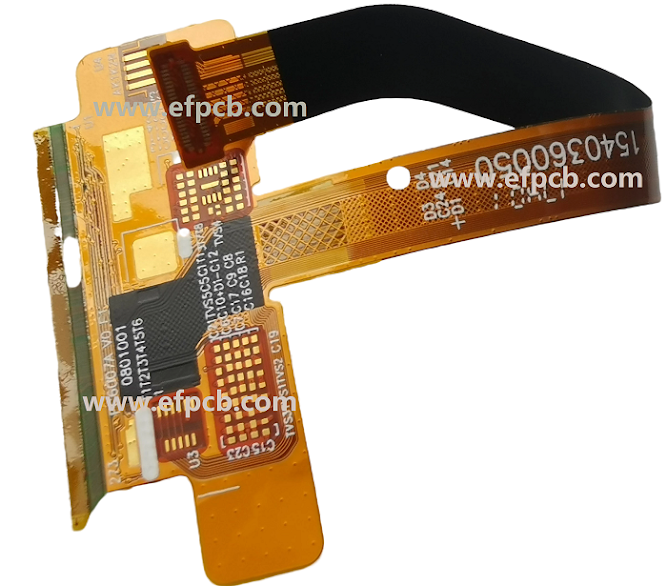

- Flex PCBs.

- Rigid-Flex PCBs.

Today

we will discuss Flexible PCB. Flexible PCB is also popularly

known as flex prints or Flex PCB. Flex Circuit Board is a

special type of circuit board that has the most convenient feature i.e

flexibility. It means as per the desired shape and size of the device the board

can be installed. More specifically, these types of PCBs are used in

high-density and high-temperature applications. Flexible PCBs are made up of

copper or copper foil. Sometimes, it is also made up of alloys including

aluminum, nickel, gold, silver, etc.

Flexible PCBs have a high demand nowadays based on their user-friendly approach. In the electronics sector like automotive, electro-medical devices, telecommunications, aero-space, etc. its application is significant. If we analyze its manufacturing it is embedding the flexible circuit into a rigid board and then layering up is done.

Let us discuss the advantageous features of Flex Circuit Boards. Being flexible allows the designer a great scope for proper placing and operation of the applications. Apart from this also it takes less space resulting in reduced weight. The optimal use of space ensures better thermal management. So choose a reputed flexible PCB maker and get the all required benefits.

Comments

Post a Comment