The Essential Role of Radio Frequency PCBs in Modern Technology

Transmission

lines are structures intended to direct electromagnetic signs starting with one

point then onto the next with insignificant bending or misfortune. They are

vital in Radio Frequency PCB to keep up with signal honesty, diminish

reflections, and relieve impedance bungles that could some way or another

corrupt exhibition.

Key Ideas

• Trademark Impedance (Z0): Trademark

impedance is a crucial property of a transmission line, addressing the

proportion of voltage to current in a unit length. It decides how successfully

a transmission line moves power from a source to a heap. For RF PCBs, keeping

up with steady trademark impedance all through the follow is imperative to

forestall signal reflections and keep up with ideal sign quality.

• Engendering Deferral: The time it

takes for an electromagnetic wave to go along a transmission line from the

source to the objective is called proliferation delay. This becomes basic in RF

PCB plan, where timing is urgent for legitimate sign synchronization and

handling.

• Reflections and VSWR: High VSWR

demonstrates the presence of reflections because of impedance crisscrosses. In

Radio Recurrence PCB configuration, limiting VSWR is fundamental to forestall

signal corruption and keep up with signal honesty.

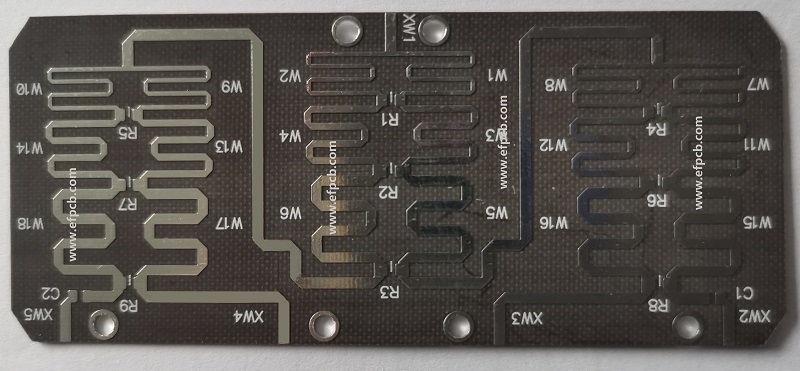

Transmission Line Types

• Microstrip: They comprise of a guide

on one side of the PCB and a ground plane on the other. Microstrip lines are

somewhat simple to manufacture and are appropriate for plans with moderate

frequencies.

• Stripline: Stripline transmission

lines are sandwiched between two ground planes, giving better safeguarding and

decreased radiation contrasted with microstrip lines.

• Coplanar Waveguide (CPW): CPW

transmission lines include a guide sandwiched between two ground planes, with

the sign follow uncovered on the top. CPW lines offer great seclusion and are

reasonable for RF plans that require insignificant radiation.

Plan Contemplations for

RF PCBs

• Follow Width and Dispersing: The

components of the transmission line, for example, follow width and dividing,

influence its trademark impedance. Exact command over these aspects is urgent

to keeping up with the ideal impedance.

• Dielectric Steady (εr): The

dielectric material utilized in the PCB influences the engendering pace of the

sign and, thusly, the trademark impedance. Understanding the dielectric

properties and their effect on the transmission line is fundamental.

• Signal Honesty and EMI: Appropriate

establishing and safeguarding methods are fundamental in Radio Recurrence PCB

plan to relieve electromagnetic obstruction (EMI) and guarantee signal

respectability. Cautious consideration should be given to establishing systems

and sign steering.

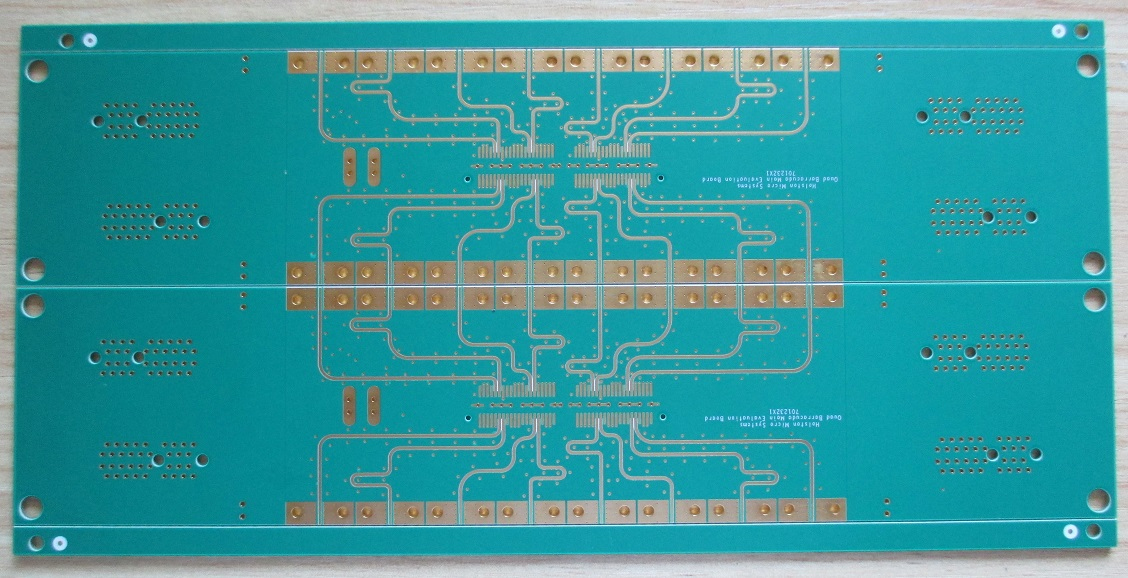

Radio

Recurrence (RF) PCBs are pivotal in the present innovation driven world,

empowering the usefulness of gadgets that depend on high-recurrence signals.

From cell phones and satellite frameworks to radar and specialized gadgets, RF

PCBs are basic to guaranteeing ideal execution and unwavering quality.

RF

PCBs are intended to deal with high-recurrence signals with negligible sign

misfortune and obstruction. This requires particular materials and exact

assembling methods to keep up with signal trustworthiness and diminish

electromagnetic impedance. Excellent substrates, for example, those produced

using materials like Rogers or Teflon, are normally used to accomplish the important

presentation guidelines.

One of the critical difficulties in RF PCB fabricating is overseeing impedance and sign uprightness. Engineers should cautiously plan the PCB format to guarantee steady impedance and limit signal reflections, which can debase execution. High level reenactment instruments and methods are utilized to address these difficulties, guaranteeing that RF PCBs meet severe execution measures.

As innovation propels, the interest for RF PCBs keeps on developing, driven by advancements in media communications, purchaser gadgets, and aviation. Makers are continually refining their cycles and materials to stay up with advancing necessities and higher frequencies.

Next: Powering Electronics Innovation: PCB Assembly Services in China

Comments

Post a Comment