Find out about PCB Material Stock

The meaning of RF microwave PCB

is that they have parts that convey RF or microwave signals. In recurrence

from, 50MHz to over 2 GHz there is variety in the signs, and in parts among RF

and Microwave PCBs and other PCB types, these frequencies characterize the

distinctions.

These applications commonly need

overlays with particular electrical, warm, mechanical, or other execution

qualities that then, at that point, surpass those of conventional standard FR-4

materials. We comprehend the high dependability and tight resistance

necessities of most applications because of numerous long stretches of

involvement in PTFE-based microwave cover.

There is a particular gathering

of RF and microwave PCBs that has both FR-4 and PTFE or different materials

together in the very stack up that are called Half and half PCBs. Around these

high-innovation RF Microwave PCB, you can get more data on these

half-and-half plans and our interesting abilities.

PCB Material Stock

As different materials are

exceptionally specific, we truly do hold a critical supply of items in our

stockroom. Not all organizations are ready to do that given the significant

expense of conveying stock so they can answer rapidly.

Planning, high-innovation circuit

sheets manufactured with high-recurrence overlays can be troublesome in light

of the responsiveness of the signs and the difficulties that accompany dealing

with the warm intensity move in your application. In standard PCBs, the best

high-recurrence PCB materials have low warm conductivity versus the standard

FR-4 material utilized.

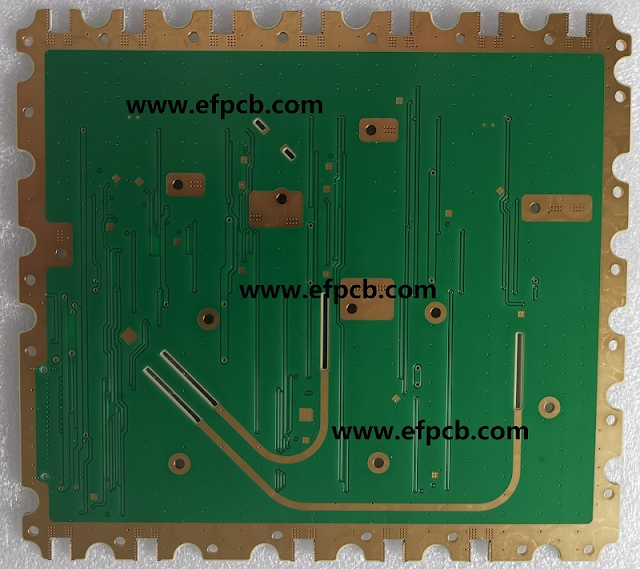

RF and microwave signals have

aversion to the commotion and contrasted with conventional computerized circuit

sheets they have a lot more tight impedance resiliences. Controlled follows can

assist with causing the plan to perform most proficiently by using ground plans

and utilizing a liberal curve span on impedance-.

As the frequency of a circuit is

recurrence-reliant and material-subordinate, PCB materials with higher

dielectric steady (Dk) values can result in more modest PCBs. It is because the

scaled-down circuit plans can be utilized for explicit impedance and recurrence

ranges.

Having a comprehension of the temperature coefficient of dielectric steady, coefficient of warm extension (CTE), dielectric consistent, warm coefficient, dissemination factor (Df), and even things like relative permittivity, and misfortune digression of the PCB materials accessible will assist the RF With microwaving PCB fashioner in making a vigorous plan that will surpass the necessary assumptions.

Comments

Post a Comment