How to Assemble PCB and the Process Involved in It

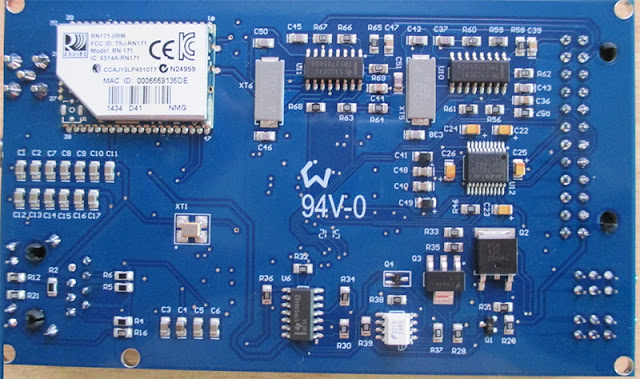

The PCB get-together help is a significant piece of gadget fabricating. Its job is to mount electrical parts on printed circuit sheets with the assistance of surface mount innovation and afterward it is plated with the assistance of opening innovation. PCBA gathering in China is likewise alluded to as printed wiring gathering, gadgets gathering, and circuit card get-togethers. By Taking a gander at the various amounts of circuit sheets to collect, there are a couple of different sorts of gathering like clump PCB gathering, the model gets together, little group PCB gathering, and high volume PCB get together.

How You Can Gather PCB?

The cycles of PCB gathering

contrast contingent upon the circuit board necessities, for example, the

twofold-sided, without lead, fine-pitch, sans halogen, and so on.

Notwithstanding, the essential advances that are required are part obtaining,

PCB/Gerber records check, PCB and SMT stencil producing, SMT gathering, BOM

check, and PTH Get together.

Interaction of SMT Get together

SMT get-together is generally

programmed.

From the start, PCBs and parts

are checked. PCBs are then put on the feeders. In the part rolls, there is a

putting of uninvolved SMDs with impressions 0201, 0402, 0603, and 0804 on the

fast mounting machine.

Consistently these PCBs are sent

into the SMT patch glue printing machine, in which there is printing of the

weld glue on the PCB cushions.

Assessment of bind glue (SPI). On

PCBA China, the SPI machine keeps an eye on the bind glue's shape and

thickness. The expected PCB cushions should be completely covered by the

Certified weld glue printing and contingent upon the item prerequisites, the

thickness goes from 0.09mm to 0.15mm.

SMD gathering. Individually the

PCBs are sent into the rapid mounting machine and practical mounting machine.

On the expected PCB cushions the SMDs are picked and set naturally.

Reflow welding. PCBAs are of

course sent into the reflow welding broiler consistently. In the stove, there

is preheating of PCBAs, then, at that point, they are warmed and afterward left

to chill off. During this interaction, there is softening of patch glue and

afterward, it cements, and afterward, the SMDs are bound onto the circuit

board.

The PCBAs are sent through the AOI machine. The outer layer of the PCBAs is checked with an infrared camera filter, and with the assistance of set-up boundaries, the machine examinations and afterward thinks about the pictures. An AOI specialist keeps a watch on the machine screen and records each conceivable issue that is available.

Assuming that any sort of imperfection is found on the PCBA assembly China, it is returned for revamping. A revamped PCBA is kept in separation from other PCBAs.

Follow our Facebook and Twitter for more information about our product.

Comments

Post a Comment