Have A Brief Idea about Metal Core PCB

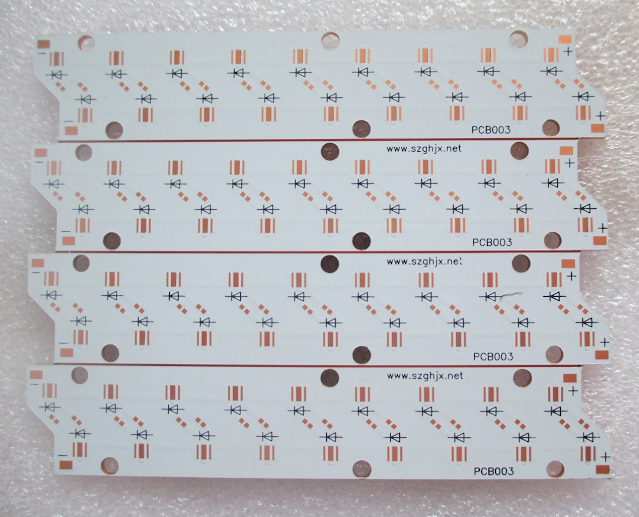

A metal core PCB,

or MCPCB, is a type of printed circuit board that uses a metal core as the base

material. MCPCBs are commonly used in high-power and high-temperature

applications, where traditional FR-4 PCBs would not be suitable.

The metal core of an MCPCB is

typically made of aluminum, copper, or a combination of the two. The metal core

provides several benefits over traditional FR-4 PCBs. First and foremost, the

metal core acts as a heat sink, dissipating heat away from the components on

the board. This is particularly important in high-power applications, where the

components can generate a significant amount of heat.

In addition to heat dissipation,

the metal core also provides excellent rigidity and durability. This makes

MCPCBs ideal for use in applications where the board may be subjected to high

levels of stress or vibration.

MCPCBs can be manufactured using a

variety of techniques, including etching, milling, and laser cutting. The metal

core is typically coated with a layer of dielectric material, which serves as

the insulation layer for the circuit traces. The circuit traces are then

applied using standard PCB manufacturing techniques.

One of the key design considerations

for metal core PCB is thermal management. The

thickness and material of the metal core, as well as the placement and size of

the vias, can all have a significant impact on the thermal performance of the

board. It is important to work with an experienced MCPCB manufacturer to ensure

that the board is designed and manufactured to meet the specific thermal

requirements of the application.

MCPCBs are commonly used in a

variety of high-power and high-temperature applications, including LED

lighting, power supplies, motor control, and automotive electronics. With their

excellent thermal performance and durability, MCPCBs are an ideal solution for

many challenging applications.

One important consideration when

designing an MCPCB is the choice of metal core material. Aluminum is a popular

choice due to its low cost and excellent thermal conductivity, but copper may

be more appropriate for applications that require high electrical conductivity

or electromagnetic shielding.

In addition to the metal core and dielectric material, metal core PCB may also include additional features such as surface-mount components, plated through-holes, and special coatings for corrosion resistance or improved thermal performance.+

Follow our Facebook and Twitter for more information about our product.

Comments

Post a Comment