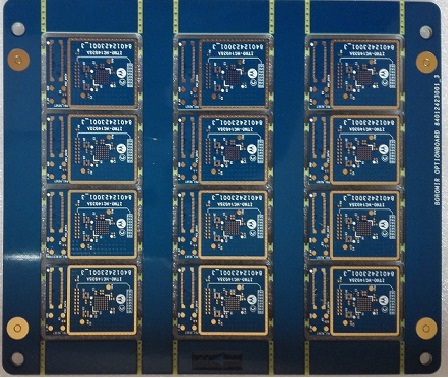

Get to Know About HDI PCB

High-Density Interconnector is

referred to as HDI. HDI PCB Manufacturing contains

smaller vias; fewer capture pads, and a greater connection pad density. They

also have finer gaps and lines. It helps make the instrument smaller and

lighter while enhancing electrical performance. HDI PCB is the ideal option for

pricey laminated boards with a high layer count.

To fulfill the electrical needs of

high-speed communications, the board should have a range of features, including

high-frequency transmission capabilities, impedance control, decreased

redundant radiation, etc. Due to arrays and electronic component reduction, the

board's density must be enhanced. The board is even offered with outstanding

high density as a consequence of the leadless, fine pitch packaging, and direct

chip bonding assembly procedures.

HDI PCB offers a plethora of

advantages, including high frequency, compact size, and fast speed. It is the

main component of personal computers, mobile phones, and portable computers. At

the moment, HDI PCB is widely employed in various consumer goods, such as MP3

players and gaming consoles.

Using equivalent or minimal

amounts of space, HDI PCBs use the most contemporary technology to increase the

functionality of circuit boards. The tiny semiconductor packages and components

that offer extraordinary attributes in cutting-edge new products like

touchscreen tablets are what are driving the progress in board technology.

High-density features on HDI Boards include laser micro-vias, thin high-performance materials, and tiny

lines. More functions may be performed per unit of the area due to the higher

density. The routing precision needed for high pin-count chips used in mobile

devices and other high-tech goods is provided by these kinds of multifunctional

architectures.

Owing to the tiny pads and fine pitch of the circuitry on the circuit board, the location of the components on the board demands higher precision than a normal board design. Leadless chips need special soldering techniques, extra assembly, and repair processes. The HDI circuitry is thinner and lighter; therefore the PCBs may fit into tighter locations and have less mass than traditional PCB designs during HDI PCB Manufacturing. Even the smaller size and lighter weight show that there is a decreased chance of getting hurt by mechanical shocks.

Comments

Post a Comment