The Crucial Guide to PCB Assembly Consumables and Materials

PCB Assembly China

is a complex process that requires a careful selection of materials and

consumables to ensure the production of high-quality electronic devices. From

soldering materials to cleaning agents, each component plays a crucial role in

the efficiency and reliability of the final product.

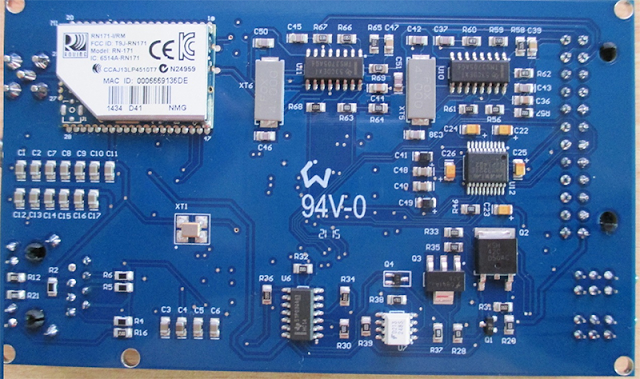

PCB Substrates

At

the heart of every PCB is the substrate, typically made of materials like FR-4

(Flame Retardant-4) or flexible materials for more intricate designs. The

choice of substrate depends on factors such as thermal conductivity, rigidity,

and cost. FR-4, a composite material composed of woven fiberglass cloth and an

epoxy resin binder, is widely used due to its excellent mechanical and

electrical properties.

Soldering Materials

Soldering

is a critical step in PCB Assembly China,

and the materials used in this process significantly impact the final product's

reliability. Common solder alloys include lead-based and lead-free options.

Lead-free solder has become more prevalent due to environmental concerns, and

it typically consists of tin, silver, and copper. Flux is another crucial

component, aiding in the soldering process by preventing oxidation and ensuring

proper wetting.

SMT Stencils

Surface

Mount Technology (SMT) stencils play a vital role in applying solder paste

accurately to the PCB. These stencils are typically made of stainless steel or

nickel and feature precise openings corresponding to the solder pads on the

PCB. The quality and precision of the stencil directly impact the solder paste

deposition, affecting the overall quality of solder joints.

Solder Paste

Solder

paste is a mixture of solder alloy particles and flux, providing the necessary

material for creating solder joints during reflow soldering. The particle size,

alloy composition, and flux type all contribute to the soldering process's

effectiveness. Proper application and control of solder paste are crucial for

achieving reliable and consistent solder joints.

Conformal Coating

Conformal

coatings are applied to protect PCBs from environmental factors such as

moisture, dust, and chemicals. These coatings enhance the board's resistance to

corrosion and environmental stress, ensuring the longevity of the electronic

device.

Assembly Tools

Comments

Post a Comment