What are the Inclusions in a PCB fabrication drawing?

A

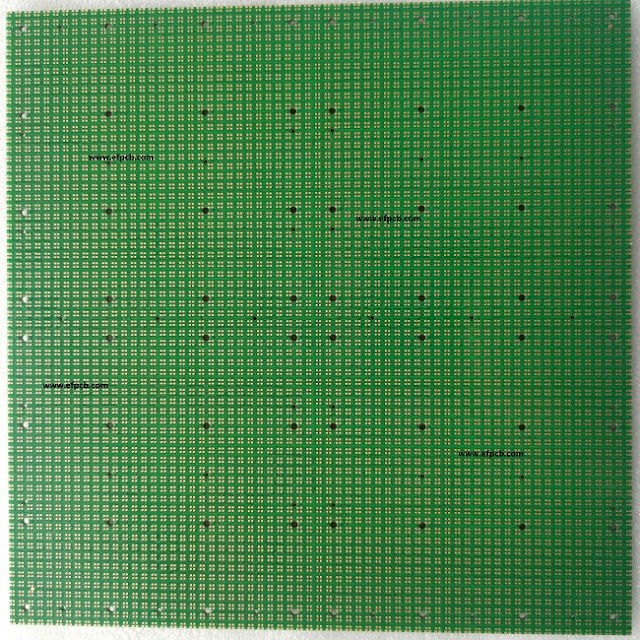

PCB Fabrication drawing refers to an

ultra-critical file that carries information pertaining to the actual

construction of the circuit board. The extent of thorough work put in drawing

the PCB fabrication drawing increases the probabilities of obtaining a circuit

board to fit your specifications. A fabrication drawing defines certain

parameters like layer stack up, board outline, drill chart and a lot of other

features. An effective assembly drawing coupled with a fabrication drawing is

very helpful in assembling the circuit board.

What

do all these terms mean? Specifically, what is the relation between a PCB

Fabrication Drawing and an Assembly Drawing?

Since

the name has it, a fabrication drawing entails important information that is

compulsory in putting up the board. An assembly drawing on the other hand

describes all the necessary details as to how each component shall connect to

the board.

There

are certain elements that should be included in a PCB fabrication drawing.

Dimensions

That

is why it is necessary to mention the dimensions of the board as that will

provide an understanding of how much PCB material will be needed to cover the

board.

- Length of the

board

- Its width

- Thickness

- Outline

- Tolerances

There

also has to be a Board Outline and it instructs where the cuts have to be made,

the holes, the radii, and other distances from the origin and the like.

- Drill chart

- Which layers need

drilling

- Drill Sizes

- Tolerance, and

more.

The

drill chart contains certain symbols associated with the hole size. It gives

information on whether the inside of the holes are plated or not and much more.

Layer Stack Up

This

is a clear indication that Layer Stack up has a lot of influence on some of the

other facets of the project.

- Material

- Thickness

- Copper Weight

- Surface Finish

- Tolerances

- Controlled

Impedance

Based

on the Controlled Impedance specification, the manufacturer can then consider

other aspects such as dielectric constant, spacing, trace width and more.

In

a wide variety of software, the PCB

Fabrication drawing can be created. But,it is not limited to:

- Eagle EDA

- KiCAD

- Altium Designer

- PCB Fabrication

Notes

With

the following information, it will help to include PCB Fabrication notes in

addition:

- Requirements of

Controlled Impedance

- Manufacturing

specifications

- Raw material

specifications

- Plating details

- Details of Solder

Mask

- Gold fingers, if

present

- Any specifications

concerning the position of holes.

- If via-in-pad

exists then mention

- Blind/Buried via,

if any

- Some more

tolerance includes board tolerance & plating & etching tolerance.

With today’s modern methods of PCB manufacturing, why not have the best PCB manufacturing solutions. Even better, the PCB Fabrication services will be taken up a notch from the specialists here as they will accept all kinds of the newest technologies.

Next: Know About the High-Density Interconnect (HDI) Flexible PCBs

Comments

Post a Comment