High-Density Interconnect (HDI) PCBs: Lightweight, Compact, and Reliable Solutions

Miniaturized

electronic circuit boards are used in various industries: consumer electronics

and communication systems, automotive & aerospace industry & health

care & several other applications. In all these industries, HDI circuit boards or high-density interconnects (HDI PCBs) are of immense value. HDI

technology shall allow the designing and manufacturing of products with low

form factor at nearly the same cost of manufacturing as the standard products

with the same quality, performance, and board reliability.

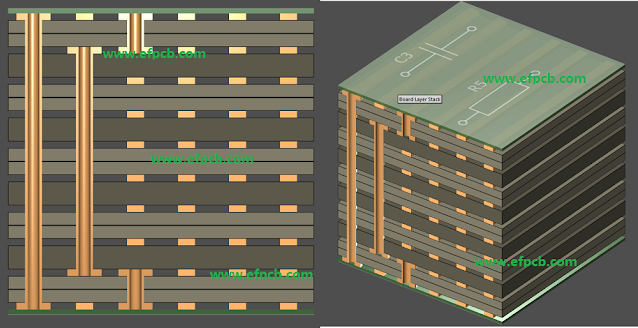

High-Density

PCBs

High

density of placements of components and / or denser interconnection provided on

any printed circuit board makes it a high density PCB or high density

interconnect PCB. These PCBs provide even more wiring density per unit area

than the previously used PCBs.

High-density

PCBs consist of:

- Microvias

- Blind and

buried vias

- Layers with

through vias

- coreless

construction with pairs of layers

- An

assortment of coreless constructions with layer pairs

- This means

having no substrate construction to create any form of electrical

connections.

- More of

these interconnections

New

high-density boards are dense and create a new set of rules that define smaller

dimension boards, pads, vias, spaces, and trace width. Due to the dense wiring

pattern in the HDI boards, they are classified as lightweight, miniaturized

circuit boards having less number of layers. The potential of saving PCBs

within a particular product is worthwhile to substitute a few PCBs with an HDI

board.

Advantages

of HDI PCBs

High-density

printed circuit boards are widely used in portable electronics like touch

panels, mobile phones, tablets, PC, digital cameras, laptops, etc High density

interconnect boards are tinier in size compared to regular boards but they

don’t in any way affect the efficiency of the board. The advantages of

HDI PCBs are:

Light

weight and compact sizing – The use of more components on

both sides of HDI circuit boards results into more compact and lighter

PCBs with additional function.

Multiple

boards - With the help of HDI technology, the amount of

the raw material, the number of layers and sometimes even the number of boards

can be less, which creates over cost effect.

Minimized cost and High Density –This shows that the performance increases with increased reliability in HDI boards due to closer components & high transistors per unit area. Compared with other printed circuit board designs, there are relatively fewer signal integrity problems, and a considerable reduction in crossing delays, lost signals, etc. Micro vias also have a tremendously transformative effect as compared to through holes on the reliability of the HDI board because of the small aspect ratio of micro vias and their superior fabrication.

The time to market – The manufacturing of PCBs for the HDI circuit boards also offers remarkable design for productions here the time for market is reduced considerably. In addition, / with HDI boards/ design and testing is also accelerated.”

Comments

Post a Comment